CEOs, along with present sequence and procurement managers, find it difficult to predict wherever the next “bottleneck” is likely to be, that’ll affect the method of getting pieces, end creation lines and trigger dissatisfaction with the finish clients.

A fresh support by “IDAS – Global Distribution Assurance Services”, offers a solution to this issue by letting them control their relations and communications with the manufacturers in a aggressive way.

Industries which generate items especially if they’re advanced or complex including the automotive, aviation and electric industries require to cope with a weakness: late supply of parts. These industries generate items which include many tens of thousands of pieces, and have to handle the challenge of managing suppliers, stock and generation lines. Being a puzzle isn’t total if actually one portion out of one thousand is lacking – so is a plane that’s lacking a prop or a digital system because that component’s supply was postponed by the supplier. The organization might find it self with a product stuck on the construction point without to be able to carry on creation before the birth of the long-awaited shipment. Beyond the financial injury in this condition, it entails that the end client will not get his buy at the appointed time – which could hurt the company’s reputation ,reliability and profitability.

“We seen that to be able to permit global businesses , little , moderate and big , to utilize enormous firms that use clear performance indexes, it is inadequate to have only quality and aggressive products. Along with that they should give their consumers with promptly supply supported by a system that will share these records with whole openness in real time claims Lior Katz ,CEO of “IDAS – global distribution assurance solutions ” “which specializes in advanced source string solutions. The organization was created in 1985 and since then has been helping suppliers to work with the greatest aviation and automotive organizations in the world .The numerous decades of task have deepened the business’s understanding and ideas regarding the weakness in the present chain field.

“We recognized what a offer cycle is and what’s the required SLA (Service Stage Agreement ) That is expected of providers In these industries. We came to the understanding that production industries are by nature industries which are reactive as opposed to practical”, adds katz “procurement and source sequence managers will need activity when elements are not being provided on time. Just when the production point has ended ,as the elements haven’t been shipped in an appropriate fashion may they start running after the vendors and parts. The various tools at the businesses’disposal allow it to be probable to identify the problem when it occurs ,but it’s also late. Thesolutions that endured for years weren’t successful enough and unsuccessful in preventing delays in supply, preventing of creation lines and dissatisfaction of the conclusion customers “.

For example, to that, Katz pertains to a product in the area of traffic get a handle on that had to generally meet a large number of model orders each month. A delay in the supply of ceramic capacitors which was needed for the generation of the items didn’t allow timely distribution to a sizable customer in china and taiwan, which light emitting diode the consumer to threaten to change to the competitors.

Recognize a product that might be postponed

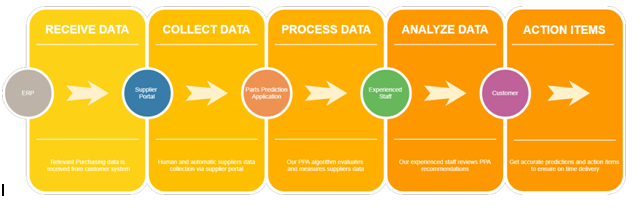

At “IDAS – Global Delivery Assurance Solutions ” it was realized quite a while before that this function approach requires a change. The initial substantial stage on the subject had been performed in the 90’s ,once they established an internet-portal-based information discussing tool where real-time revisions for supply ,creation knowledge, expected items and deliveries are available .Thousands of providers global use this instrument today. “We made a method that provides whole transparency to consumers and shows exactly what is going on in the generation lines. This is how they have the assurance to accomplish company with manufacturers, following seeing they meet up with the requirements of promptly supply” says Gali Katz , manager of the supply chain in the company , who has over 25 decades of knowledge in managing offer organizations in the electronics and high-tech industries. This permits vendors to be competitive in the market in which they perform and to be involved in tenders where service and on time distribution are vital parameters “.

This was perhaps not the conclusion of the goal for “IDAS– International Distribution Confidence Services“ he said. In reality, it was just the warm-up for the following large issue: Adjusting a from being tuned in to to be able to search forward and foretell the expected shortages. “We recognized that there is a need for a holistic alternative, not only a particular logistical solution. 2 yrs before, we achieved the final outcome that people may upgrade our technique and engineering and develop an algorithm that anticipates which manufacturers and what parts is going to be difficult”, says Lior Katz. “Nowadays there is an entire world of ERP and MRP methods for arrangement and controlling materials, and they do what’s required, but ultimately they are all reactive – enable a reply only when the situation is in their full swing. Actually, they are intra-organizational methods that do maybe not handle the companies’side. We have created a solution that mixes the algorithm and the service that accompanies it to be aggressive, handling the problem beforehand by early recognition and handling of the problematic parts before the status converts from green or yellow to red”.

The traffic lights aren’t just an image. At PPA ,the application developed by the organization, the statuses of different pieces are highlighted with one of these colors ,letting the user to easily recognize something that’s in danger to be delayed. The application form evaluates data from a big amount of resources and draws ideas centered on that. The algorithm weighs the info and draws a forecast ,whether a part can appear punctually around another 90 days .It utilizes the supplier’s supply history, the number of known components he has in stock and creation, his relevant obtain get confirmations, and eventually his support index.

“We know how to quantify the degree of company to an index and to weigh the parameters in order that they develop a focused strategy that will predict whether or not parts may arrive on time. There could be an item arrives in fourteen days and its provider always matches the required supply date .On one other hand, there is a required product for another two months – therefore the client isn’t dealing with it, but their company posseses an record of tardiness, a place the customer is definitely not alert to,” claims Katz. “Our system can paint that object in red so your firm will look after it in advance”.

Identify the fragile url in the string

In accordance with Gali Katz, nowadays a lot of the active indexes are retroactive mathematical prices.”IDAS–International Supply Confidence Companies” changes that and anticipates ahead. “Essentially, this can be a answer produced by a variety of past, provide and future. The device requires previous knowledge, through the interaction with the company and the current data – and based on this predicts the future. It shows the problematic objects in red and tells an individual:’ Here is your problem, emphasis about it ‘.Thus, organizations in addition to offer chain and procurement managers can estimate where the long run “bottleneck” may be. The device detects which areas may jam their construction lines ahead of time, thus keeping personnel time that could have been lost on needing to recalculate a path .This covers a typical issue of procurement persons, who die in information and handle the search and option of issues as opposed to preventing them in advance and enabling successful and us abandoned work.

” What we propose to agencies is by using IDAS Companies to control the communications with the manufacturers” Katz provides and suggests.Take people and use people to be sure you are certain to get the areas on time. There is a cooperation from the suppliers’portion as well, because this can be a condition that everyone else advantages from. Till today they have been obtaining endless calls and messages and wasted their time. Today they handle the underside range: to produce and provide products. They simply have

to pay a few minutes every week updating the info through our portals or representatives. IDAS clients be given a system that is fully managed by people, as we are the ones who communicate with the vendors and assure that they can cooperate in providing the current information and information in the portal. The result is an clear to see data, so the client can emphasis just on what’s essential and use his time effectively, which is price a lot of money. We give the consumer a complete company that permits him to proactively control the source string, with an increased exposure of the important parts”.

IDAScustomers testify so it works. “I see that being reflected within our’urgent’file .It has less and fewer lines. When there is a regular tracking from both sides, with an increased exposure of possible issues – this somewhat reduces the setbacks, “says one customer. PPA shows extraordinary usage of logical methods, with the capacity to change the way in which suppliers understand customers and identify issues in advance. This can be a hands-on method that’s very essential” , says yet another customer.

“Our product efficiency is summed up in what we contact’the four E s ‘,” Katz summarizes.

• Ensuring providers On Time Supply

• Increasing suppliers traceability and awareness

• Efficient manufacturers dangers administration

• Effortless vendors connection